PORTABLE CONTAINER OPERATION SOLUTION

- 07/04/2016

- 7311

Automating the manipulation of container positioning by GPS and GIS application software will increase the speed of professional operations, minimize errors with human factors, optimize the container capacity of the port.

PORTABLE CONTAINER SOLUTIONS

A - CURRENT STATUS OF PORTAL CONTAINER

Operation of lifting containers by container lifting machines requires determining the location of containers by parameters of STAY-ROW-TIER (BAY-ROW-TIER). Whenever the container is unloaded or lowered, it is required to re-update the location into the business data to serve the monitoring and real-time monitoring of each container position in the port.

Currently, BAY-ROW-TIER position is updated manually by forklift driver. Container operators require container truck driver staff to memorize thousands of positions in the port. Container operators not only reduce the speed of business operations but also are very confusing. To lift or lower a container not only to update the position of the container, but also to update the position of all the containers that are moved to unload the container to be lifted, meaning that the employee must manipulate a lot of visits update the position of containers in 01 container lift-down.

Automating the manipulation of container positioning by GPS and GIS application software will increase the speed of professional operations, minimize errors with human factors, optimize the container capacity of the port.

To determine container position based on coordinates and altitudes, accuracy below 20cm is required in all directions. However, when GPS was first put into service, the US military was concerned about the possibility of enemy forces using GPS signals available globally to guide their own weapons systems. To avoid this, "raw" signals (C / A) transmitted on L1 frequencies (1575.42 MHz) have deliberately been degraded, by causing random deviations in the copper signal. lake, equivalent to an error of about 100 meters in distance. Therefore, GPS application to determine container location requires advanced GPS technology to correct the error of availability.

In addition, container-position determination applications require dynamic measurement and instantaneous processing, so the rectification signals must be processed at the container forklift and directly query the position data. All ports to calculate BAY-ROW-TIER at any time.

B - THE POSITIONING TECHNOLOGY IS HIGH ACCURACY

1. Differential Global Positioning Technology Container (DGPS)

Micro-signals are usually played in UHF radio form. These frequencies are also often used for radio near the sea, near large rivers and harbors. Project of Global Positioning Station Network (GPS) project in Vietnam territory was implemented by Vietnam Department of Surveying and Mapping since 2012. The project includes Central Processing Station in Hanoi, about 12 measuring stations. Geodetic network, fixed satellite positioning station (DGPS) cover the entire territorial waters of Vietnam and about 30 stations in two key economic areas in the North and the South.

The advantage of DGPS is that it only needs one large capacity container station for the whole area.

However, DGPS is oriented to marine navigation applications and deep measurement, so the error is greater than 1m. With a location far from the reference station and unusual weather conditions, the error can be up to 3-5m. In addition, the method of differential correction via UHF radio waves is not suitable in conditions of harbor with many corners and steel blocks that cause interference. Therefore DGPS technology containers are not suitable for container positioning applications.

2. High-precision real-time dynamic measurement technology - RTK (Real Time Kinematic)

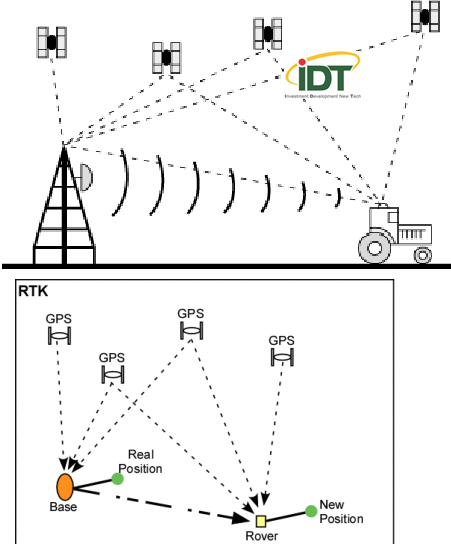

RTK is a real-time dynamic measurement technique. In principle, RTK is similar to DGPS. However, in RTK measurement techniques, the base station - base transmits the phase measurement value to the rover station. The dynamic station will establish phase measurements in double-form for processing. So RTK is also called DGPS for phase measurement.

RTK usually uses an ON-THE-FLY (OTF) start-up process, in which the boot is performed while the receiver is moving. The satellite lock loss cycle can be ignored and no static start is required to redefine multivalued parameters. There are many techniques to increase the accuracy of RTK in a narrow area such as placing a receiver in known locations.

Since the phase measurement value is accurate to mm, the positioning accuracy can reach cm or dm depending on the N-parameter parameter solver in phase measurement. If 100% of the multi-valued parameters are solved, we will have the fix solution is the most accurate solution. If only 1 part is solved, we have a partial test and get a float solution if we cannot solve the multivalued parameter.

Successfully solving multivalued parameters based solely on phase measurements at the time of measurement is a challenge. Also the accuracy depends on the distance between the base station and the rover station, the number of concurrent observation satellites and the movement speed of container forklifts.

However, with the average accuracy at dm level, RTK measurement method is completely suitable for automatic container position determination problem.

C. APPLICATION OF RTK TECHNOLOGY - GPS TO DETERMINE CONTAINER LOCATION

Through analysis of real-time dynamic measurement methods, RTK GPS is more feasible because of its high accuracy and reasonable price. Moreover, the RTK GPS model works stably, independent of the environment.

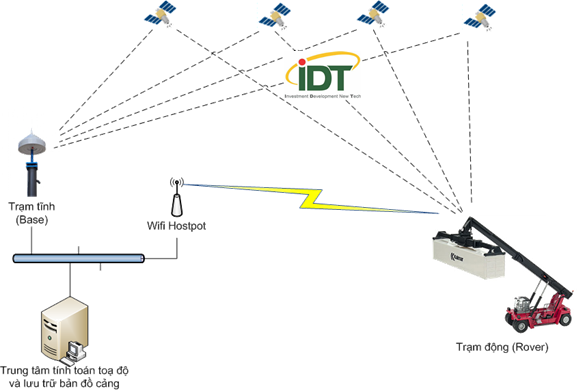

RTK model - GPS application to determine the position of the Container in the Port as follows:

The model here includes a static station built at the specified position (error less than mm). The station will collect satellite signals to compare the satellite coordinates obtained with its current standard to calculate the error and send this error to the Rover station (container forklift) for Rover station to adjust. its coordinates again.

The area of Dinh Vu Port is quite small with a width of 500m and a length of about 600m, so the method of sending rectification signals from Base station to Rover station via Radio waves is optimal for the following reasons;

· Radio sets designed to transmit rectification data reach a distance of 10 Km.

· In a distance of 600m, the radio signal is very strong, stable against interference caused by container stacks.

After receiving coordinates adjusted from Rover station, Rover station management software on container forklift will be based on the available database coordinates to determine which Bay, Row, Tier of the container has been dropped. down.

The error of vertical and horizontal station coordinates after rectification will be less than 10 cm.

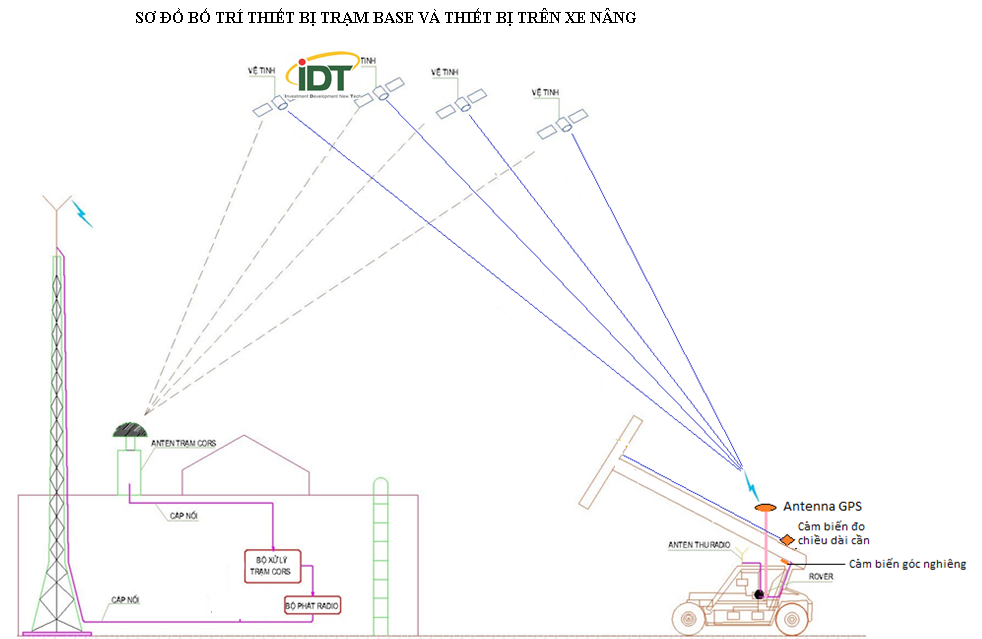

Configure RTK-GPS system at Dinh Vu Port

1. Base station: 01 set.

· Include 01 antenna to receive satellite signals on the roof.

· A central processor is located in the warehouse office.

· The extension signal cable is connected from the receiving antenna to the central processor

2. Set of signal corrections through Radio waves: 01 set.

· Including 01 Radio transmitter set in warehouse office.

· 01 antenna placed at the top of the GPS column is available.

· 01 signal cable is connected from a Radio transmitter to the antenna on the top of the column and a GPS antenna model and the actual radio transmitter column is as follows:

3. On container forklift.

Put on 01 container forklift including the following equipment:

· 01 Antenna leaves the satellite signal on top of the vehicle.

· 01 processor placed in the vehicle.

· 01 Antenna receives the rectification signal placed on top of the forklift.

· Accessories:

+ 01 signal wire connected from GPS Antenna to processor.

+ 01 signal cable connected from the corrected Radio Antenna receiver to the car-mounted processor.

+ 01 RS232 cable to connect to an existing industrial computer on the vehicle.

+ 01 power supply stabilizer to supply power from the electric system of forklift.

+ 01 software communicates with the driver to drive the container confirmation, allowing read the coordinates information and sending to the server.

D. METHOD OF DETERMINING THE LOCATION OF CONTAINER

A container will be located by x, y and altitude coordinates h.

The RTK - GPS solution allows accurate measurement of all three figures, but when applied to actual ports, it will generate the following problem: When the antenna receives satellite and antenna signals to receive rectification signals from the station The base is placed too close to the stack stack, the signal will be disturbed and the current coordinates cannot be determined. Therefore, both antennas must be placed on the top of the forklift to ensure that the coordinates are always correct. Thus RTK - GPS system only allows to determine the coordinates of the forklift only.

In order to determine the location of container placement, it is necessary to know the distance from the coordinates of the vehicle to the coordinates of the container and the height of the container compared to the ground. We use two types of sensors to get the above data:

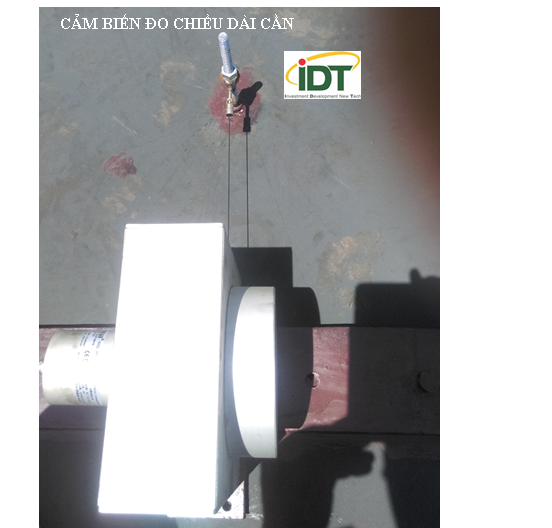

Sensor for tilt angle and sensor for measuring length.

01 sensor measuring tilt angle will be attached close to the lifting lever of the forklift. When the level of the vehicle”s hand is tilted upwards, the sensor will measure and transmit the signal to the central processor.

The tilt sensor has an accuracy of 0.5%, which allows accurate determination of the tilt angle of the forklift arm against the ground.

Tilt angle sensor consists of 02 parts.

Wire box part: As a coil with a length of 20m, one end of the coil will be fixed to the Container gripper frame. As long as the handle of the forklift is extended, the rope will be extended accordingly. When the driver needs to return, the coil is rolled up automatically by the oven system in the box.

Encoder part: When the length of the wire changes, the drive system inside the sensor will turn the rotation resistor and change the output voltage from 0 - 5V. This voltage is linear with coil length. Based on the measured voltage from the sensor sent, the central processor will calculate the length of the coil or is the length of the forklift truck.

Knowing the right hand length, the tilt angle of the hand and the fixed parameters of the vehicle completely calculate the position of the forklift and the height of the container at the position that has just been placed.

With a very small error of the sensor measuring the length and measuring the above angle, the height H of the container is calculated from the two sensors above with error less than 10cm.

E. DIAGRAM OF LAYOUT BASE AND EQUIPMENT IN FORKLIFT

F. SOFTWARE SOLUTION

The system includes 03 software:

1. Software to calculate coordinates

Includes programs:

· The program calculates the coordinates of Base station.

· Calculating rectification data

· Calculate the coordinates of Rover station on the basis of integrating satellite data and rectification data sent from Base station.

These programs have been pre-loaded into Base and Rover stations.

2. Software for reading position of Container on forklift

This software is installed on the forklift and performs the following functions:

· Read coordinates data sent from Rover station

· Read data from sensor of length measurement and measure tilt angle.

· Send the above data to the server.

· Receive and display container location on industrial computers on forklifts.

· Create minimalist interface to communicate with the driver.

3. Software on the server

Installed on the server located in the server room of Dinh Vu Port.

The function of this software is as follows:

· Developing a map of container locations in the port.

· Receive coordinate data, tilt angle from software installed on forklift.

· Calculate the position of the container

· Return location results on software on forklift.

· Exchange results of real-time positioning with the PLC-TOS software of Dinh Vu Port, direct results from RTK-GPS system directly into the container management software system of Dinh Vu Port.

· The data transmission between software on forklifts and software on the server is carried out via the Wifi network of the Port. However, in case the Wifi system is broken, the software of RTK-GPS system still allows Offline operation to ensure continuity in container handling operation in the port.

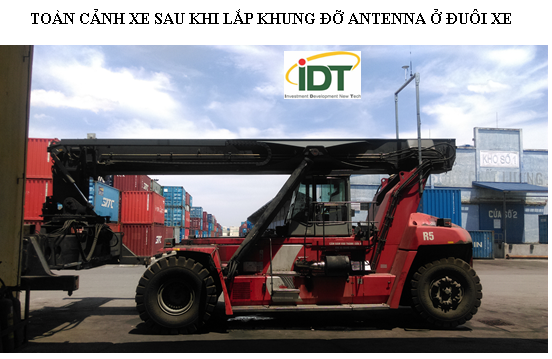

G. ACTUAL PICTURES OF INSTALLATION EQUIPMENT ON FORKLIFT OF DISTRICT VU PORT

TOÀN CẢNH XE SAU KHI LẮP KHUNG ĐỠ ANTENNA Ở ĐUÔI XE

HÌNH ẢNH ANTENNA TRÊN KHUNG ĐỠ

CẢM BIẾN ĐO GÓC NGHIÊNG VÀ CẢM BIẾN ĐO CHIỀU DÀI CẦN

Comment

main.comment_read_more